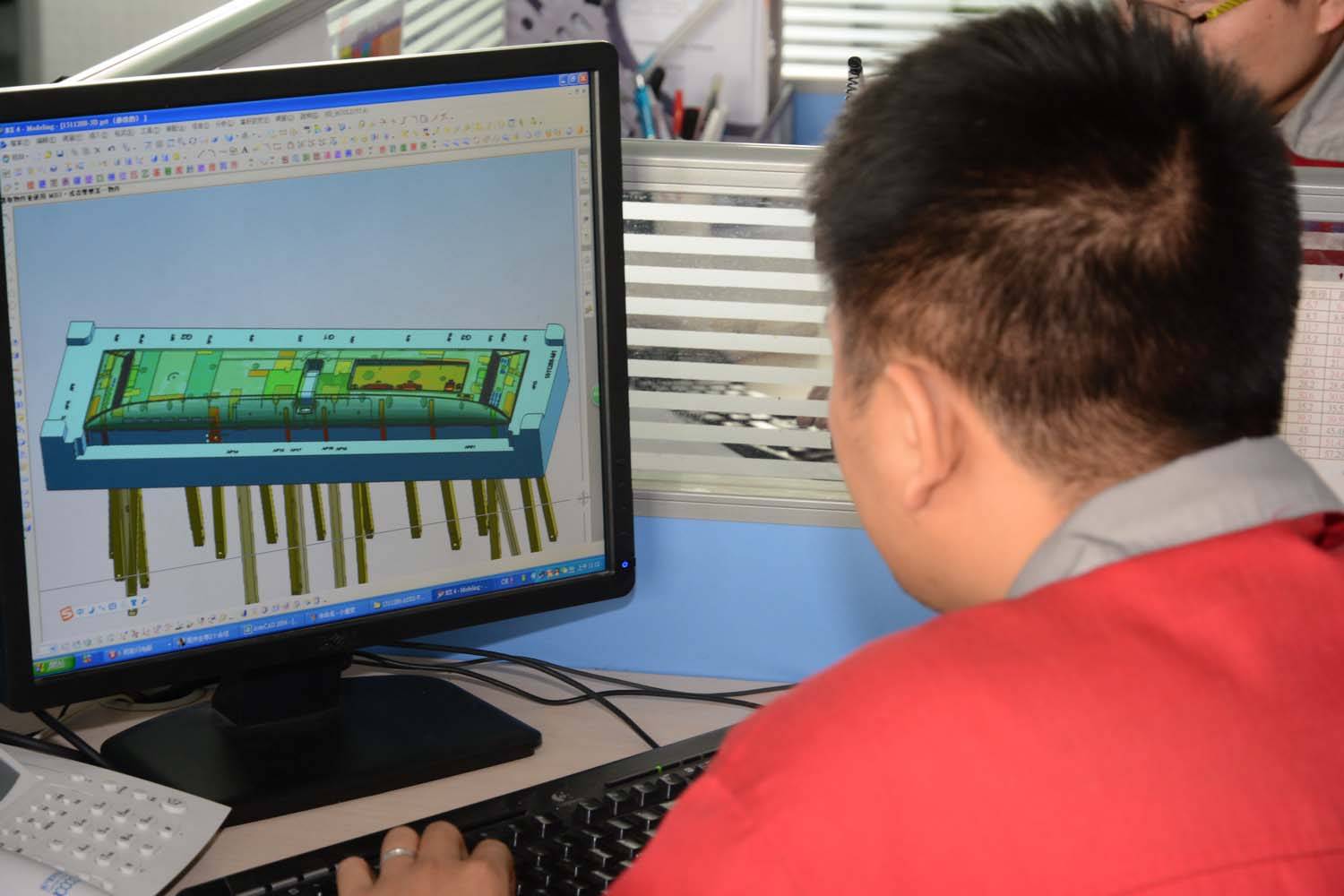

The birth of an excellent Mold base cannot be separated from the design of a professional team. How to design the adjustment structure of the mold skeleton, how to make the mold stronger, easy to assemble, with a novel appearance and unique functions,these are the things we think about.Take a look at our a customized High Precision Plastic Injection Standard Mold Bases

The structure of mold is important, which determines whether the function of mold is stable in different application scenarios.

Our professional design team has designed a structure that can be adjusted, allowing users to decide their own Angle.

Name | High precision plastic injection mold bases / standard mold base plastic injection mould base |

Place of Origin | China Dongguan |

Brand Name | Senlan |

Model Number | customized |

Product Material | ABS,PP,PC,PE,POM,PU,PVC,TPU, etc |

Keyword | injection fabrication for medical equipment battery cover |

Mould base | European Standard |

Mould material | SKD11/51/61,SKH-9,S136, NAK80,XW-42,2738,8407,etc. |

Design software | UG,UG, PROE ,CATIA, SOLIDWORK, CAD,etc. |

Mould life | 300000-1000000shots |

Tolerance | +/-0.001mm |

Surface treatment | as customer’s requirments |

mould type | injection fabrication for medical equipment battery cover |

Processing equipment | CNC machine,Automotic lathe machine,EDM machine,Wire-cutting machine,Milling/Grinding machine,Punching/injection machine,Ultrasonec cleaning machine,etc. |

Detection equipment | Projector,Calliper,Height gauge,Screw gauge,Hardness gauge,etc |

Cavity | Single / Multi cavities,as customer’s requests. |

Runner | Hot / Cold |

Mould life | 300000-1000000shots |

Specification | 20 years machining parts processing experience;Precision tolerance less than 0.001mm;Depends on customer’s requirements. |

Delivery | Shipping sample in 30 days after payment,or according to customer’s requests. |

Package | PE bags add export carton for parts,Wooden case for mold,or as customer’s requests. |

1. High precision molding part.

2.You design, we customized.

3.High quality control, economic price.

4.Continuance after-sale service supports.

At Senlan, we believe that design and functionality go hand in hand. We meticulously select the finest materials and employ our exceptional craftsmanship to create molds that are not only aesthetically pleasing but also provide utmost support. Each mold is thoughtfully designed to enhance relaxation and create a cozy ambiance in any space.

Our journey started with a small workshop, but as our reputation grew, so did our production capacity. We invested in state-of-the-art manufacturing facilities, enabling us to meet the demands of our ever-expanding clientele. Our skilled artisans work tirelessly to ensure that every mold that leaves our facility meets the highest standards of quality and precision.

Over the years, we have collaborated with numerous leading brands with our exquisite molds. Our dedication to customer satisfaction has earned us the trust and loyalty of our clients, who appreciate our attention to detail and commitment to excellence.

Our team of expert engineers, with over 20 years of combined experience, reviews and enhances design plans. They prioritize high performance, cost-effectiveness, and ease of manufacturing for molds. Each design document undergoes thorough consideration of various factors to ensure the creation of exceptional products.

Q: Can you help with the design of the molds?

A: We have a professional design team. Except OEM orders, we can also help you design products.

Q: How do I find the mold product I want?

A: You can find the answer from the product list.Another way you can fill in your requirements and send inquiries to our sales engineers.

Q: What Certifications do you have?

A: ISO9001,SGS,SEDEX,BSCI,CE,ROHS, UL,certifications etc.

Q: What is the MOQ?

A: Our MOQ is 1 pcs .

Q: How long warranty can provide ?

A: We can provide 1 year product quality warranty.

Q: How to ensure quality ?

A: Please do not worry about that, each product is tested by Senlan professional technicians and QC team and we wiltest one by one to pick up the good quality for you.

A customer’s words have a more substantial impact than a company’s claims – and see what our satisfied customers have said regarding how we fulfilled their requirements.

I met the company at a trade show.You know,it is not easy to find a suitable factory,that may take you a long time and energy.Luckily I found this factory and good cooperation.

James CEO of ShiseidoFine workmanship, every detail is handled in place, the size is very accurate, and the mold material is used very well.

Phillips Buyer of NatcoDelivery on time, the price is very affordable! The service attitude of the manufacturer is very good, the product quality is excellent, it is recommended to purchase in this factory.

Zoey Founder of SanitasThe quality of the mold is very good, the cost performance is very high, the finished products are qualified, in line with my high standard requirements.

Herbert Manager of OptuneThe quality is very good, the material is very sufficient, strong and thick, the size is also very standard, fine workmanship, satisfaction!

Baron Supply chain managerNo posts found!

Get the latest news and updates straight to your email inbox

This is the fastest delivery I’ve ever received,great!Of course my customers received their products very quickly. I use this product myself,to be honest, I like it very much!

Shams W.Pawel Founder of Xpeed