Experienced In

Molds & Mould Components!

Since 2012, SenLan is a professional manufacturer of injection mould and mould parts. We have the ability to manufacture all kind of precision parts, they are commonly used in precision plastic mold, medicine mold, and precision automation machine.

Our On-Demand Manufacturing Services

SENLAN delivers high-quality moulds and precision machining parts with an incredible range of manufacturing capabilities.

From mould designing to mass production, we help manufacture products with complex geometries and high aesthetic demands.

Our skilled experts and advanced technologies allow us to deliver an extensive range of on-demand manufacturing services.

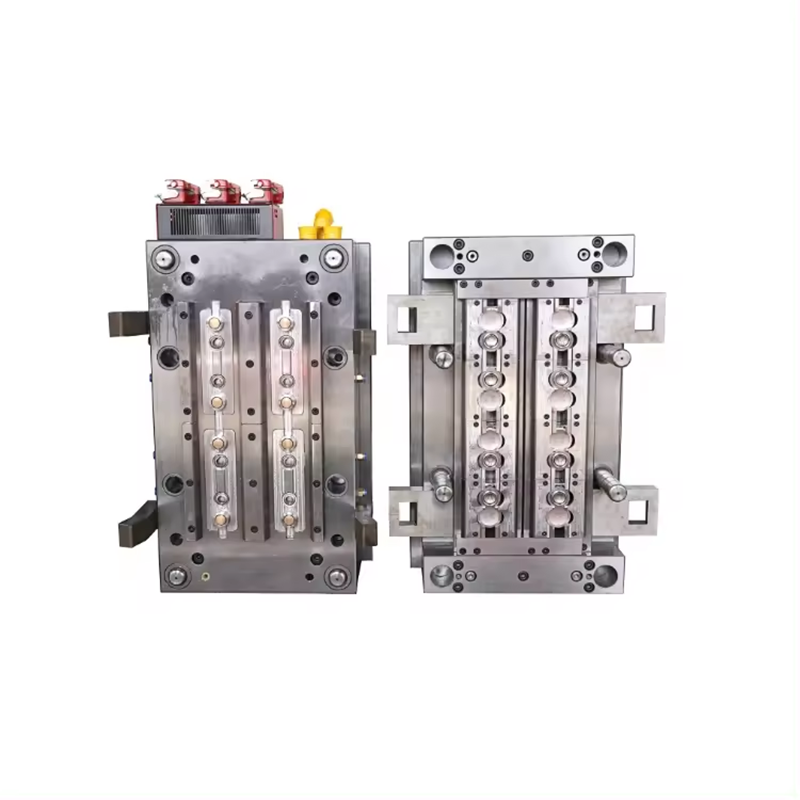

Custom Mould Center

Mould Sampls

How We Work

With extensive design experience and strong delivery capabilities, we can quickly provide a solution to meet your needs.

Get your needs

Anytime you can contact us by email, WhatsApp,phone and tell us your needs.

Design 3D drawings

Our professional designers help you design sketches when receiving your requirements.

Make a sample

We can make samples and check whether the molds are up to standard.

Confirm test sample

The sample will let you know if the mold is successful and you can do real tests.

Mass production

Our design and delivery capabilities ensure that our customers' needs are met.

Delivery & service

It is our mission to solve any problem of customers,we always put our energy into it.

Serving With Numerous Industries

SENLAN ensures superior quality and reliable functionality. We deliver high-quality moulds and precision machining parts with an incredible range of manufacturing capabilities, we offer high-quality products across several industries.

For over 12+ years, we have been a leading manufacturer in the field of molds and tooling. Our journey began with a small team of skilled craftsmen who were passionate about creating high-quality molds that would revolutionize various industries.

Back in 2005, our founder, Mr. Zhu, recognized the need for superior molds that could cater to the evolving demands of the market. Armed with an unwavering determination and a vision to excel, he established our company and laid the foundation for what would become a legacy in the field of molding.

In the process of making medical mold, the parting surface is required to be tight, and the mold accuracy is ensured by equipment processing means as far as possible. The clearance of the parting surface should be less than 0.01mm, and the cooperation gap between the push rod and the push tube of the ejecting system should be less than 0.01mm

Transparent products as far as possible to choose hot runner; Disposable medical device products need to use automatic unloading, shear gate, pay attention to the gate feeding position and dynamic model Z fixed way; The mold cooling system should adopt several separate cooling channels to reasonably control the dynamic fixed mold temperature to control the deformation of the product.

Injection mold is a tool for the production of plastic products, and it is also a tool for giving plastic products complete structure and accurate size. Injection molding is a processing method used in the mass production of some parts with complex shapes. It is composed of a die core called a front die (punch die) and a die cavity called a back die (concave die). The mold development process usually begins with an initial design that lacks detail, which can lead to an unsatisfactory product if used directly. The key parts of the design information required to start the mold design include part size, wall thickness and expected production volume.

Senlan Precision Parts Co.,Ltd. is established in 2008, is a professional manufacturer of precision mould parts. Our factory, located in the mould town–Chang’an. It is a professional company in research, development and manufacturing of precision mould components,we have over 10 years experience in this field,our advanced precision equipment and scientific quality control ensures customers satisfaction.

About Senlan

Help customers to design excellent molds and accessories, so that customers can use our molds to produce perfect products.

Founded in 2012, SENLAN Precision is an global provider of high precision molds and mold components for the injection molding industry and develops molds with the most effective and efficient production solutions.

Help customers to design excellent molds and accessories, so that customers can use our molds to produce perfect products.

Professional

WhyChoose Senlan

As an ISO 9001:2015 certified company, we strictly implement the ISO standards throughout our production lines for consistently high-quality products. Our moulds and production lines also feature cutting-edge technologies to ensure manufacturing accuracy and precision. With sophisticated testing and measuring tools in-house, we ensure every component meets your desired specifications.

15 Years Of Experience

We deliver the best solution and provide a business strategy that makes you a full professional.

Expert Support

Being self-confident makes you perfect for gaining success. Assuring the enhancement of inner-power.

Rigorous Quality Control

Get opportunity to gain technological skills that improve the innovation funnel with new tips & tricks.

High Quality Materials

To ensure the quality of our products, we require the use of the best raw materials

ISO 9001:2015

We are iso certified to ensure that each of our mold products meets the standard.

Strong Capacity

Experienced designers, trained workers, only to produce the perfect product.

Trusted By Brand Customers

What Our Customers Say About Us

A customer’s words have a more substantial impact than a company’s claims – and see what our satisfied customers have said regarding how we fulfilled their requirements.

The mold is made according to the requirements, and we have visited the factory on the spot. We can cooperate for a long time.

James CEO of ShiseidoFine workmanship, every detail is handled in place, the size is very accurate, and the mold material is used very well.

Phillips Buyer of NatcoDelivery on time, the price is very affordable! The service attitude of the manufacturer is very good, the product quality is excellent, it is recommended to purchase in this factory.

Zoey Founder of SanitasThe quality of the products is very good, the cost performance is very high, the finished products are qualified, in line with my high standard requirements.

Herbert Manager of OptuneThe quality is very good, the material is very sufficient, strong and thick, the size is also very standard, fine workmanship, satisfaction!

Baron Supply chain managerWe Offer mold solutions for the plastic packaging industry

Latest News

Our good cooperation with customers has promoted the development of the mold industry, and there are often new technologies and news updates, you can get it!

We have cooperated with each other for several times. The mold works well. The first sample is ok and can be produced normally.

Shams W.Pawel Founder of Xpeed