In the vast field of industrial manufacturing, molds are like an invisible bridge, connecting design and reality, shaping the form and function of thousands of products. It is not only an indispensable basic tool in the manufacturing industry, but also an important force to promote technological innovation and industrial upgrading. This article will explore the definition, classification, manufacturing process, application field of molds and their importance in modern industrial manufacturing, and reveal the mystery of molds as the cornerstone of industrial manufacturing.

1. Definition and classification of molds

In short, a mold is a tool used to form or replicate specific shapes and sizes. It is usually made of metal, plastic or other hard materials, and can cause raw materials (such as metal, plastic, rubber, etc.) to undergo plastic deformation or solidification under high temperature, high pressure or specific conditions, thereby obtaining the desired products or parts. There are many types of molds, which can be divided into different types according to different standards:

1. Classification by material

Metal molds: mainly used for the molding of metal materials, such as stamping molds, forging molds, etc.

Plastic molds: specially used for the molding of plastic products, such as injection molds, blow molding molds, etc.

Rubber molds: suitable for the production of rubber products, such as rubber pressing molds, vulcanization molds, etc.

2. Classification by molding process

Stamping mold: metal materials are stamped into the desired shape by pressure.

Injection mold: molten plastic is injected into the mold cavity, and plastic products are obtained after cooling.

Die-casting mold: molten metal is injected into the mold cavity under high temperature and high pressure, and metal products are obtained after cooling.

Blowing mold: plastic is blown into the desired shape by gas pressure.

3. Classification by use

Automotive mold: used for the production of automotive parts, such as body cover molds, engine parts molds, etc.

Electronic mold: suitable for the production of electronic product housings, connectors and other components.

Medical device mold: specially used for the production of medical devices and consumables, such as syringe molds, artificial joint molds, etc.

2. Mold manufacturing process

The mold manufacturing process is a complex and delicate process involving multiple links and steps. The following are the main process flows of mold manufacturing:

1. Design stage

The design stage is the basis of the entire mold manufacturing process. Designers need to design the structure of the mold and select the materials according to customer needs and product characteristics. This stage needs to fully consider factors such as the product’s molding process, demolding requirements, mold life and cost. After the design is completed, simulation analysis and optimization are required to ensure the accuracy and reliability of the mold.

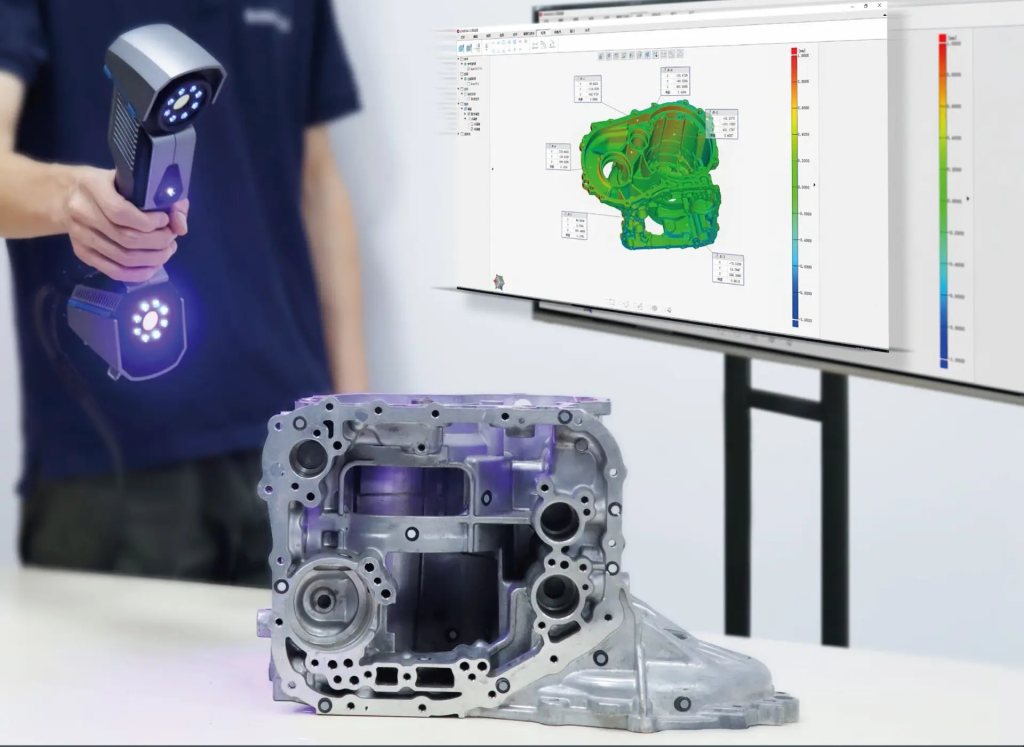

2. Processing stage

The processing stage is the core link of mold manufacturing. In this stage, various precision processing equipment and technologies are needed to process and shape the mold materials. The processing process includes milling, grinding, EDM, wire cutting and other processes. During the processing, the processing accuracy and surface quality need to be strictly controlled to ensure the dimensional accuracy and shape accuracy of the mold.

3. Assembly and debugging stage

The assembly and debugging stage is the process of assembling and debugging the processed mold parts. During the assembly process, it is necessary to ensure the matching accuracy and clearance control between the various parts to ensure the overall performance and stability of the mold. After the assembly is completed, debugging and mold trial are required to test the molding effect and production efficiency of the mold. According to the results of the mold trial, the mold may need to be partially adjusted and optimized.

4. Acceptance and delivery stage

After debugging and optimization, the mold needs to be fully accepted and tested. The acceptance content includes multiple aspects such as the dimensional accuracy, surface quality, and molding effect of the mold. After acceptance, the mold will be delivered to the customer for use. During the delivery process, detailed instructions for use and maintenance guides are also required to ensure that customers can use and maintain the mold correctly.

3. The importance of molds in modern industrial manufacturing

Molds play a vital role in modern industrial manufacturing, and their importance is reflected in the following aspects:

1. Improve production efficiency

Molds can achieve large-scale and high-efficiency production, significantly improving production efficiency. Through mold forming, a large number of products with consistent shapes and precise dimensions can be produced in a short time, greatly reducing production costs and time costs.

2. Ensure product quality

The precision and stability of the mold directly determine the quality and consistency of the product. The dimensional accuracy, surface quality and performance of products produced using high-precision molds can be effectively guaranteed. This is of great significance to improving the market competitiveness of products.

3. Promote technological innovation

The development of mold manufacturing technology is an important force in promoting industrial technological innovation. With the continuous emergence of new materials and new processes, mold manufacturing technology is also constantly innovating and upgrading. These technological innovations not only improve the performance and life of the mold, but also provide strong support for the development and production of new products.

4. Promote industrial upgrading

Mold manufacturing is an important part of the manufacturing industry, and its development level directly affects the competitiveness of the entire manufacturing industry. By improving the level of mold manufacturing technology, the manufacturing industry can be promoted to develop in the direction of high-end, intelligent and green, and promote industrial upgrading and transformation.

4. Application fields of molds

The application fields of molds are wide and diverse, covering almost all manufacturing fields that require molding processing. The following are the specific applications of molds in some major application fields:

1. Automobile manufacturing industry

The automobile manufacturing industry is one of the most widely used fields for molds. From body panels to engine parts, the production of almost all automotive parts cannot be separated from the support of molds. High-precision and high-efficiency molds provide strong production guarantees for the automobile manufacturing industry.

2. Electronic manufacturing industry

With the increasing popularity of electronic products and the accelerated pace of replacement, the demand for molds in the electronic manufacturing industry is also increasing. Molds play an important role in the production of electronic product housings, connectors, circuit boards and other components, and provide strong support for the lightweight, miniaturization and high performance of electronic products.

3. Medical device manufacturing industry

The medical device manufacturing industry has extremely high requirements for the precision and reliability of molds. Molds play an important role in the production of medical devices and consumables, such as syringe molds, artificial joint molds, etc. These molds need to ensure that the medical devices produced meet strict medical standards and safety requirements.

4. Aerospace Manufacturing

The aerospace manufacturing industry has extremely high requirements for product precision, weight and performance. Molds play an important role in the production of aerospace parts, such as engine blade molds, aircraft skin molds, etc. These molds need to be able to withstand extreme working environments and conditions such as high temperature and high pressure to ensure that the parts produced meet the high standards of the aerospace field.

molds play an irreplaceable role in modern industrial manufacturing

As the cornerstone of industrial manufacturing and the driving force of innovation, molds play an irreplaceable role in modern industrial manufacturing. With the continuous advancement of science and technology and the rapid development of the manufacturing industry, mold manufacturing technology is also constantly innovating and upgrading. In the future, molds will continue to develop in the direction of high precision, high efficiency, intelligence and greenness, and contribute more to the prosperity and progress of the manufacturing industry. At the same time, we also look forward to more technological innovation and cross-border cooperation to promote the rapid development of the mold industry and create more value for human society.