In the medical field, every detail is related to life and health. As an important part of medical equipment, the quality, precision and reliability of medical accessories and consumables are directly related to the treatment effect and patient safety. As the core tool for producing these key components, the design and manufacture of medical accessories and consumables molds are even more important. This article will deeply explore the characteristics, technical requirements, manufacturing process and application of medical accessories and consumables molds in the medical field, and show the precision manufacturing and technological innovation in this field

1. Characteristics of medical accessories and consumables molds

Medical accessories and consumables molds, as the name suggests, are molds used to produce medical accessories and consumables. Compared with ordinary molds, medical accessories and consumables molds have the following significant characteristics:

1. High precision requirements

Medical accessories and consumables often require extremely high precision to ensure that they can accurately cooperate with medical equipment during use and achieve the best treatment effect. Therefore, medical accessories and consumables molds must have extremely high manufacturing precision to meet this requirement.

2. Strict quality control

Medical accessories and consumables are directly related to the life safety and health of patients, so their quality must be strictly guaranteed. Medical accessories consumables molds need to go through multiple quality inspection and control processes during the production process to ensure the quality and reliability of the final product.

3. Diverse material selection

Medical accessories consumables are made of a variety of materials, including plastics, metals, ceramics, etc. Different materials have different requirements for molds, so medical accessories consumables molds need to have a variety of material selection capabilities to meet the production needs of different materials.

4. Customized design

Medical accessories consumables often need to be customized according to specific medical equipment and treatment needs. Therefore, medical accessories consumables molds also need to have customized design capabilities to meet the personalized needs of different customers.

2. Technical requirements for medical accessories consumables molds

In order to meet the high precision, high quality and diversified needs of medical accessories consumables, medical accessories consumables molds need to follow a series of strict technical requirements during the design and manufacturing process:

1. Precision machining technology

Medical accessories consumables molds need to have extremely high machining accuracy to ensure the dimensional accuracy and surface quality of the final product. This requires mold manufacturers to adopt advanced precision machining technologies such as CNC machining, EDM machining, laser machining, etc. to achieve high-precision mold manufacturing.

2. Material selection and heat treatment

The material selection of medical accessories consumables molds is crucial. The mold material needs to have good wear resistance, corrosion resistance, high strength and high toughness. At the same time, the mold also needs to undergo appropriate heat treatment processes to improve its hardness and wear resistance and extend its service life.

3. Cooling system design

Medical accessories consumables molds will generate a lot of heat during the production process. If the heat cannot be dissipated in time, the precision and life of the mold will be affected. Therefore, the layout and effect of the cooling system need to be fully considered when designing the mold to ensure that the mold can maintain a stable temperature during the production process.

4. Mold structure design

The structural design of medical accessories consumables molds needs to fully consider the molding process and demolding requirements of the product. Reasonable mold structure design can improve production efficiency, reduce production costs, and ensure product quality and precision.

3. Manufacturing process of medical accessories consumables molds

The manufacturing process of medical accessories consumables molds is a complex and delicate process involving multiple links and steps. The following is the main process flow of medical accessories consumables mold manufacturing:

1. Design stage

The design stage is the basis of the entire mold manufacturing process. Designers need to design the structure and select materials of the mold according to customer needs and product characteristics. At the same time, simulation analysis and optimization are also required to ensure the accuracy and reliability of the mold.

2. Processing stage

The processing stage is the core link of mold manufacturing. In this stage, various precision processing equipment and technologies are needed to process and shape the mold materials. During the processing, the processing accuracy and surface quality need to be strictly controlled to ensure the dimensional accuracy and shape accuracy of the mold.

3. Assembly stage

The assembly stage is the process of assembling and debugging the processed mold parts. During the assembly process, it is necessary to ensure the matching accuracy and clearance control between the various parts to ensure the overall performance and stability of the mold.

4. Mold trial and adjustment

Mold trial is a key link in testing the performance and quality of the mold. During the mold trial, actual production materials and process conditions need to be used for testing to evaluate the molding effect and production efficiency of the mold. According to the results of the mold trial, the mold may need to be partially adjusted and optimized to ensure that it meets the production requirements.

5. Acceptance and delivery

After mold trial and adjustment, the mold needs to be fully accepted and tested. The acceptance content includes multiple aspects such as the dimensional accuracy, surface quality, and molding effect of the mold. After acceptance, the mold will be delivered to the customer for use.

4.Application of medical accessories consumables molds in the medical field

The application of medical accessories consumables molds in the medical field is extensive and in-depth, covering many aspects:

1. Medical device accessories

Medical device accessories are one of the important application areas of medical accessories consumables molds. These accessories include various surgical instruments, implants, catheters, etc. Their quality and precision are directly related to the success rate of the operation and the patient’s rehabilitation effect. Medical accessories consumables molds ensure the high precision and high quality of these accessories through precision manufacturing.

2. Medical consumables

Medical consumables such as syringes, infusion sets, catheters, etc. are also important application areas of medical accessories consumables molds. These consumables need to strictly control the dimensional accuracy and surface quality during the production process to ensure their safety and effectiveness during use. Medical accessories consumables molds ensure the quality reliability of these consumables through advanced manufacturing processes and strict quality control.

3. Personalized medical products

With the continuous development of medical technology, personalized medical products are receiving more and more attention. These products, such as customized implants, orthotics, need to be customized and manufactured according to the specific conditions of the patient. Medical accessories consumables molds provide strong support for the production of personalized medical products through customized design capabilities.

4. Scientific research and experiments

In the field of medical scientific research and experiments, medical accessories consumables molds also play an important role. Researchers need to use molds to manufacture various experimental models and samples for disease research, drug screening and other work. Medical accessories consumables molds provide strong support for medical scientific research and experiments through high-precision and diversified manufacturing capabilities.

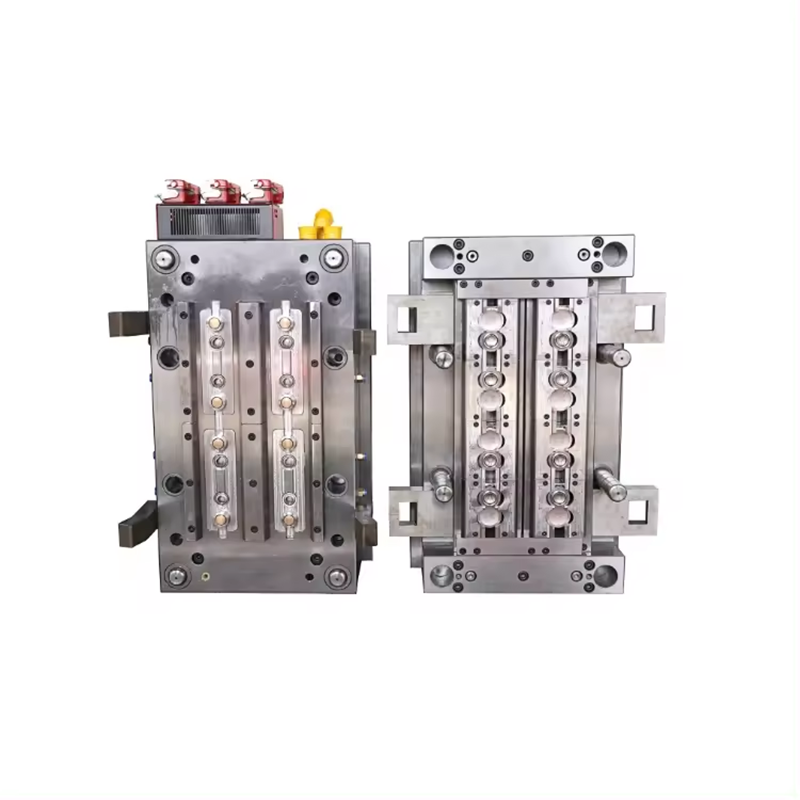

senlan custom medical accessories moulds

As an important tool in the medical field, the design and manufacturing of medical accessories consumables molds are directly related to the performance of medical equipment and patient safety. With the continuous development and innovation of medical technology, medical accessories consumables molds are also constantly improving and improving. In the future, medical accessories consumables molds will continue to develop in the direction of high precision, high efficiency, intelligence and sustainability, and contribute more to the prosperity and progress of the medical industry. At the same time, we also look forward to more technological innovation and cross-border cooperation to promote the rapid development of the medical accessories consumables mold industry and make greater contributions to human health.