Custom Quality Parts

Made With

Remarkable Capabilities

Experience our comprehensive manufacturing capabilities, meticulously crafted to meet your unique mould and production needs. Our expertise spans cutting-edge techniques like mould designing, injection molding, CNC machining, mould parts,and more. Trust us to bring your productions or parts to life.

- 50+ CNC machining equipment

- 80+ Injection molding machines

- 300+ Engineers & skilled workers

- 20000 m²+ Factory area

Custom Manufacturing On Demand

Along with our strong manufacturing capabilities, we also provide you the ability to choose the manufacturing volume and other processes that match your production needs.

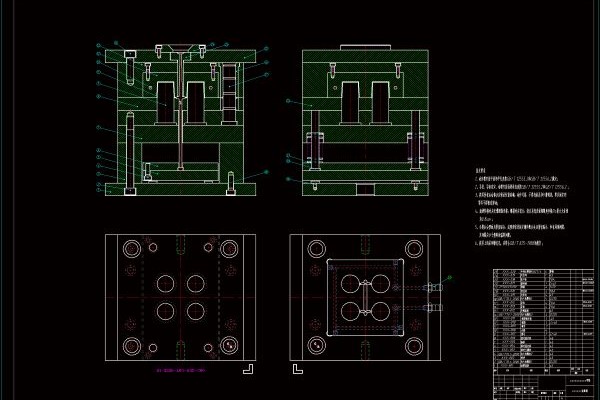

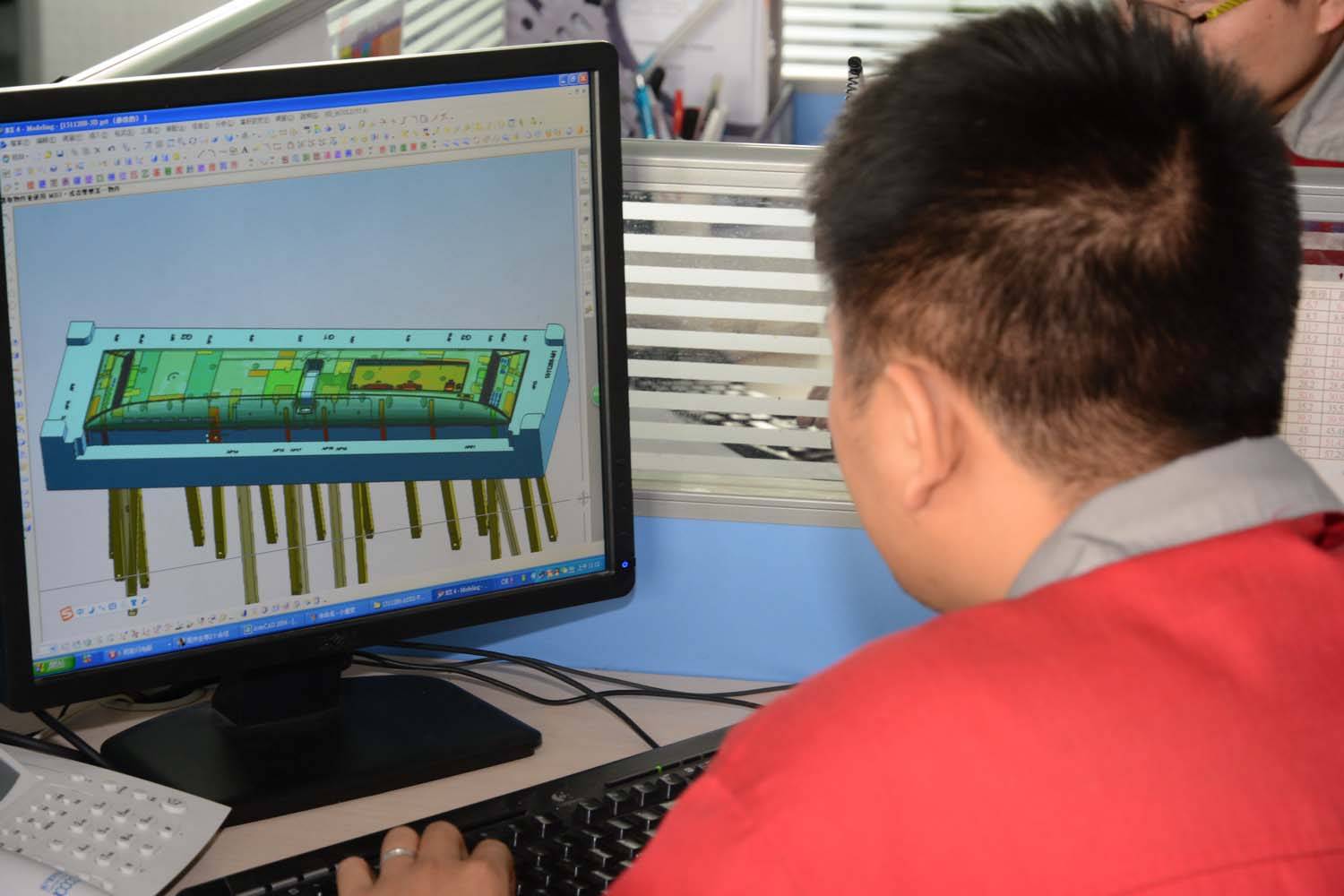

Rapid Designing

Customized Manufacturing

Service & communication

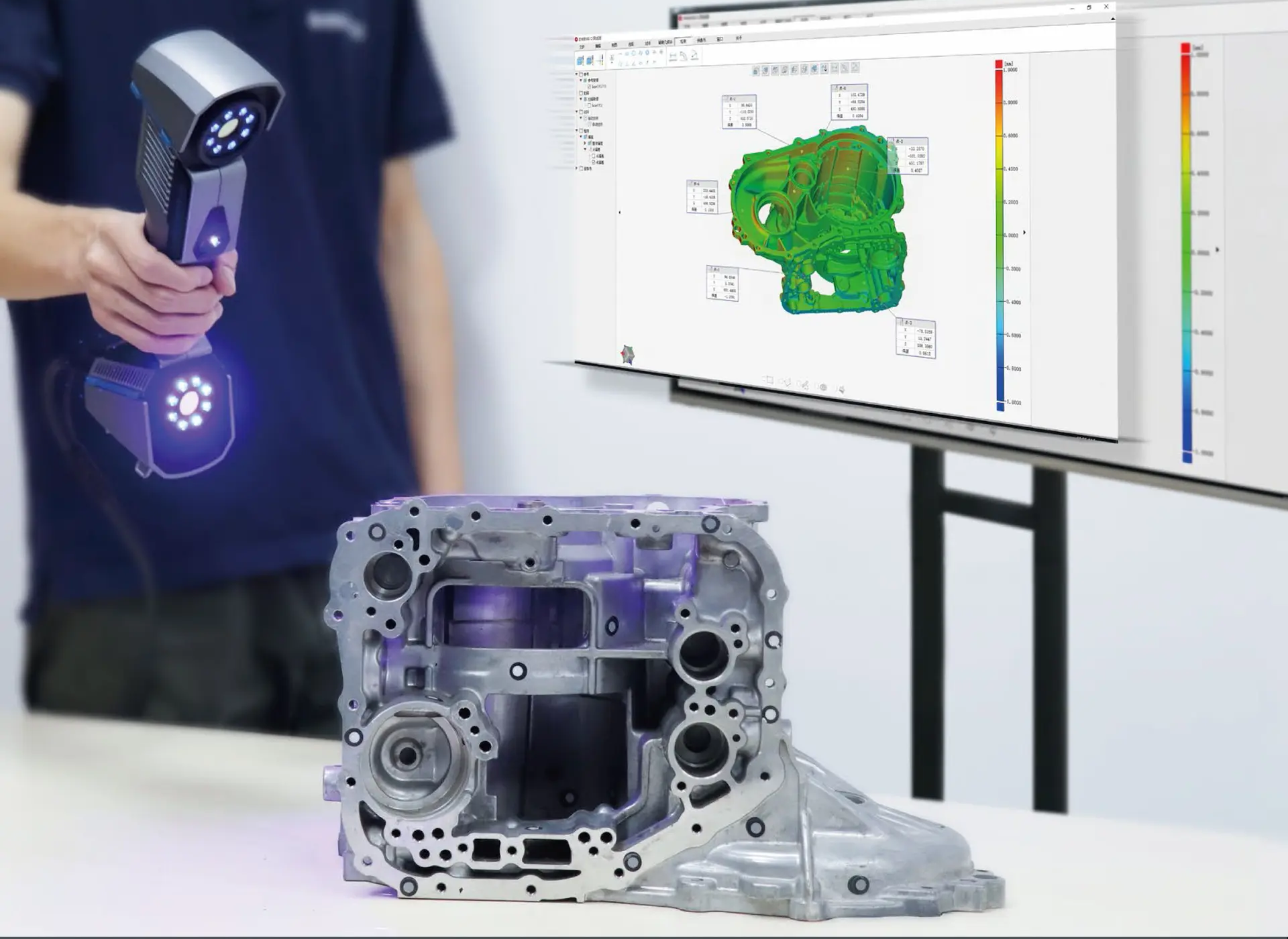

Quality Control Can Be Witnessed Everywhere

How do we focus on further improving product quality control and make efforts to this end.

Raw Material Inspection

Good raw materials are one of the key factors to ensure the mold, and we have been strictly reviewing it.

How to customize molds

Here is the process for customizing your mold.

History

Members

Brand Customers

Cases

Latest News

Our good cooperation with customers has promoted the development of the mold industry, and there are often new technologies and news updates, you can get it!