Quality Assurance For The Production of

High-Quality Moulds & Parts

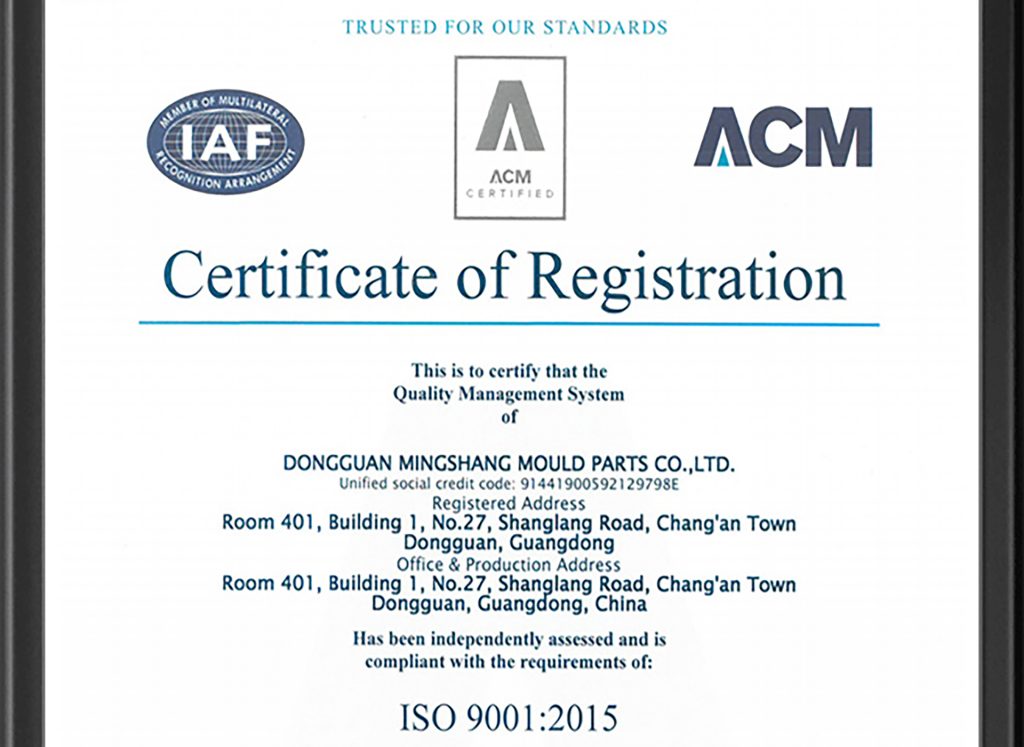

Senlan’s advanced manufacturing process, rigorous quality assurance measures, and adherence to industry standards ensure high quality, precision, and durability of your mould and mould parts.

- ISO 9001:2015 certified

- 10 + material inspection processes

- 20 + product inspection standard

How Senlan Guarantees Superior Quality

- Well-Vetted Suppliers

- Quality Materials

- Professional Mould Engineer

- Mould Manufacturing

- Rigorous Inspection

We take great care in the selection process of our suppliers. We understand the critical role they play in our operations, and therefore, we dedicate significant effort to ensure that we collaborate with the best partners in the industry.

We place a strong emphasis on the quality of materials we use. Each batch of materials that arrives undergoes a meticulous testing process, allowing us to distinguish top-grade materials from those of inferior quality.

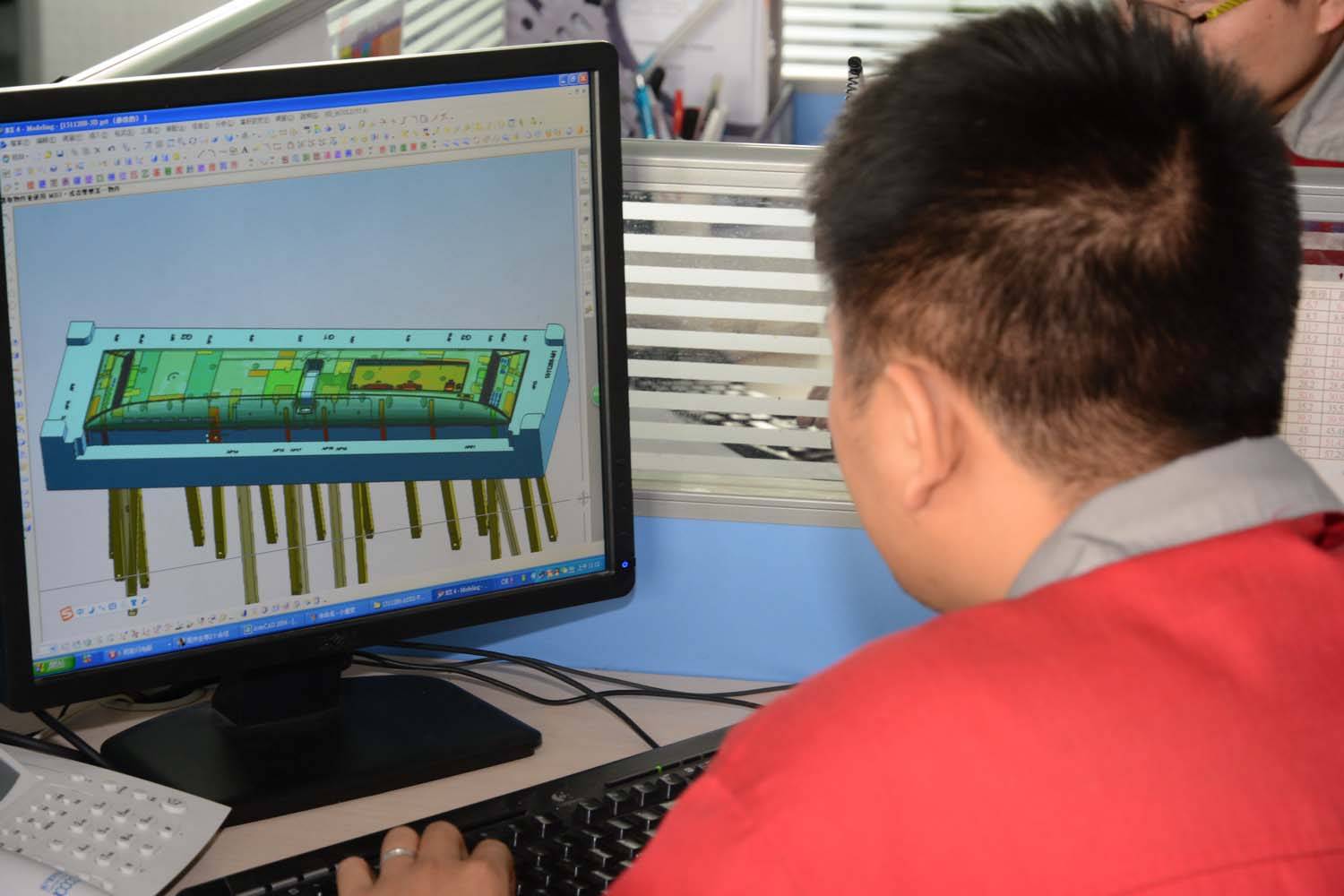

Our team of professional Mould engineers who are dedicated to reviewing and refining your project ideas. They possess the knowledge and expertise to assess the feasibility of your designs and determine the most effective approach for creating the final prototype and production parts.

We have implemented a lean manufacturing workflow that follows the ISO-2768-m and ISO-2768-c standards, specifically designed to achieve tight tolerances.

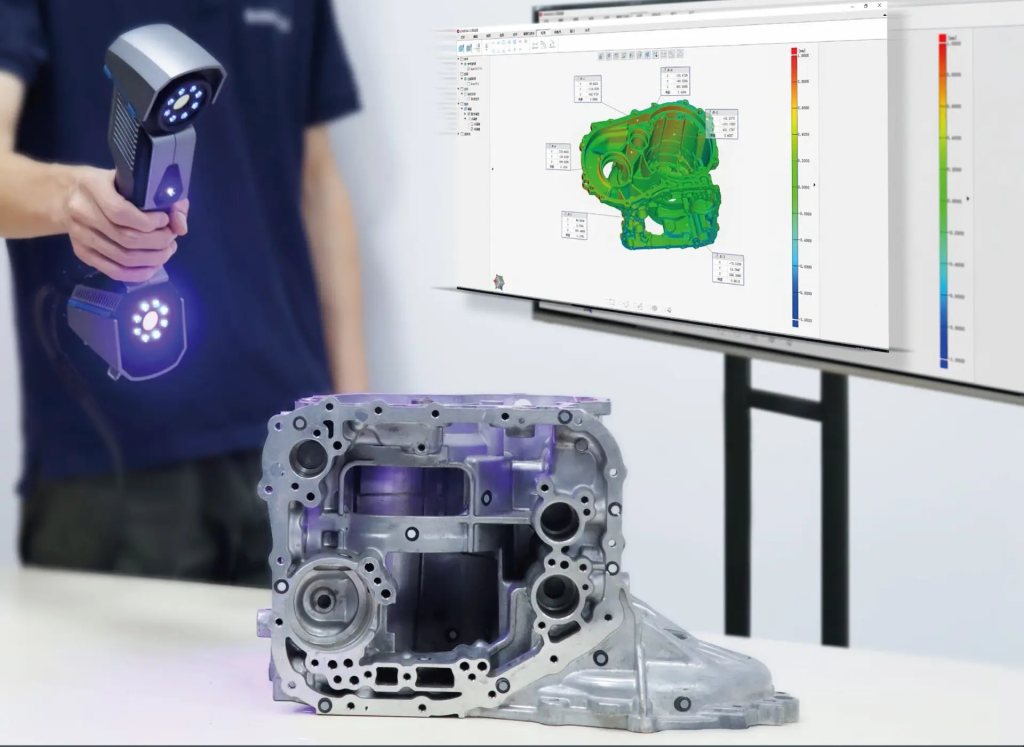

We prioritize rigorous inspections throughout our production process. Our dedicated Quality Control (QC) employees conduct a comprehensive series of inspections, including material inspection, processing inspection, and finished product inspection.

Specific Practices for Quality Assurance

Mould Pre-production

Technical assessment

Technical assessment

Material verification

Material verification

On-site inspection system

On-site inspection system

In-process quality control

In-process quality control

Mould In-production

Mould Final production

Inspection report

Inspection report

Packaging

Packaging

ISO Certifications &

Quality Reports

We have gone the extra mile to ensure that our operations align with the highest industry standards. To demonstrate our commitment to quality and excellence, we have proactively pursued and obtained recognized certifications from reputable organizations.

- ISO 9001:2015

- ISO 13485:2016

Visual Inspection

In this stage, we confirm if the product or part meets the customer’s appearance requirements. We consider the product’s color, texture, and other physical attributes.

Dimensional Inspection

We inspect parts with simple structures using vernier calipers, micro-caliper, and height gauges. We also use the CMM machine to measure its dimension accurately if complex products

Performance Inspection

We test the functionality and performance of the produced component. For instance, for parts with threadings or threaded holes, we inspect the assembly to ensure the parts fit.

First Article Report

In this final stage of the inspection process, we provide our clients with the final inspection report. This report gives a rundown of all the inspection processes and results.

Material Certifications

We can provide a RoHS report according to the customer’s request that verifies the compliance of a specific material or product with the RoHS directive.